In his classic In Search of Excellence: Lessons from America’s Best Run Companies, Tom Peters states that ‘sticking to the knitting’ is one of the success factors of the largest companies. In loose translation, it means sticking to your job.

When writing about Logistics, he even states in one of the chapters:

Many enterprises have taken heed and determined that inbound and outbound transport and warehousing are consequential processes of their business rather than fundamental or core processes. This has fueled growth of the logistics industry and expansion of thousands of 3PL organizations.

Sounds reasonable. Without going into details, it is impossible to find any fallacies in this reasoning. So why aren’t all industry leaders following Peters’ advice? Why do they run their own Logistics instead of outsourcing warehouse operations?

Writing about what to think about when planning the Logistics of an online store, I answered this question from the perspective of small and medium-sized enterprises in the eCommerce channel.

However, if you are responsible for a large-scale business, you have to face other challenges. I realized it a few years ago when managing a Supply Chain of a retail chain. Back then I was thinking how to handle a new sales channel.

But I will write about this particular case another time. This article is about whether and when it is worth using 3PL services. It is meant for those who need support in rethinking their Supply Chain. Therefore, from the article you will learn:

- What exactly is a Logistics operator?

- What are the sensible reasons for outsourcing Logistics?

- What are the common mistakes in thinking about external Logistics?

- How to determine if Logistics outsourcing is for you?

What is 3PL really all about?

But let’s start from the very beginning. What is a Logistics operator, a company offering a 3rd Party Logistics service, or 3PL for short?

Without going into book terms, it is a Logistics operations outsourcing service. It consists in separating some functions from the company’s organizational structure and outsourcing them to other specialized entities. Top Logistics operators include organizations such as Raben, DSV, Rohling Suus, and many others.

You will find the list of the largest 3PL companies at the end of this article.

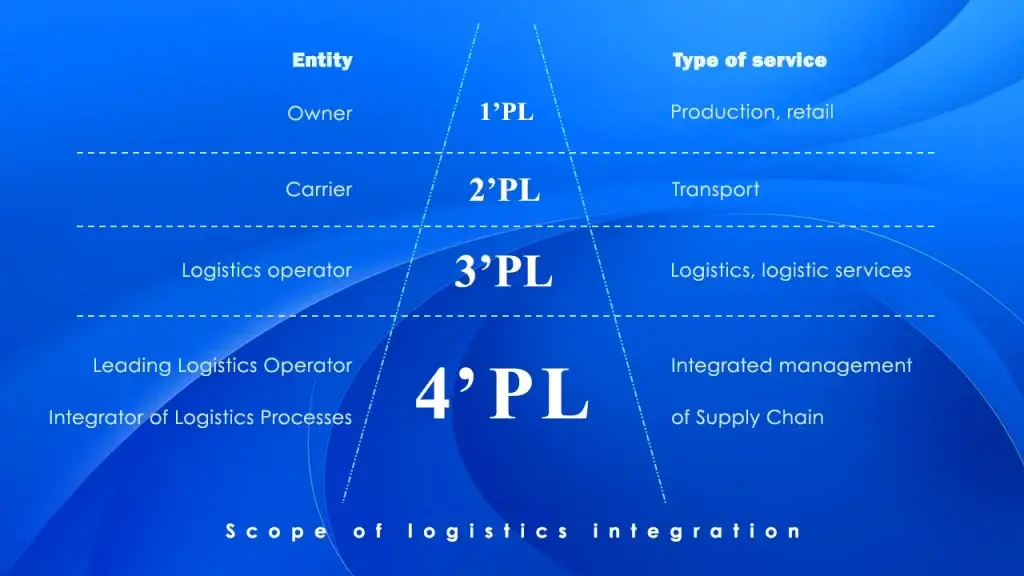

But why the term third-party instead of simply other-party? This somehow results from the history of the development of Logistics operators’ services. The path that the operators traveled is well illustrated in the graphic below.

Source: Transport company or Logistics operator? Dariusz Krasoń

1PL is internal logistics. 2PL is the outsourcing of transport services which are relatively simple compared to warehouse operations. Therefore, they are usually the first step in separating Logistics outside the organization.

In turn, 3PL is a full range of physical Logistics. It includes the receipt and storage of goods and the execution of customer orders. Often it also involves also additional services such as completing sets, displays, labeling products, and possibly their foiling.

Today 4PL is also mentioned, which is a service for managing the entire Supply Chain. Along with the responsibility for ordering goods (in retail companies) or semi-finished products and raw materials (in manufacturing companies).

Sensible reasons for choosing 3PL

So, is outsourcing of the above-mentioned Logistics operations a sensible business solution?

Over 90% of Fortune 500 companies use 3PL carriers. Most often by purchasing storage and international transport services. In some cases, also domestic transport and labor-intensive additional processes.

Why do they do it? Below you will find three sensible reasons along with a list of examples.

Lack of key competences

Most often, the reason for choosing a Logistics operator instead of your own Logistics is the lack of appropriate competencies in the organization.

Of course, over time, all competencies can be acquired. You can hire or train people. Build or rent a properly equipped warehouse. But what if the scale of the business requiring completely different Logistics is small in relation to the core activities of the organization?

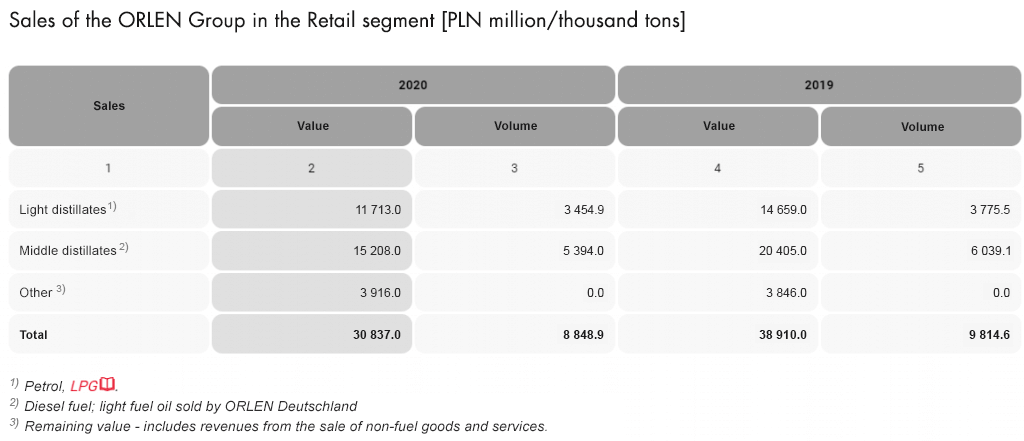

For example, Orlen is in such a situation. It is the largest network of petrol stations in Poland and at the same time a commercial network, because practically every one of 1800 stations also sells non-fuel products.

Source: Orlen. Integrated Report 2020.

Non-fuel products include food, FMCG products, CPG, as well as the press. This is a typical assortment in convenience stores, the Logistics of which differ significantly from the Logistics of liquid fuels.

Orlen achieves less than 10% of its turnover on this assortment, which can be seen in annual reports. That is why it handed over warehouse operations to ID Logistics.

Undoubtedly, the scale of Orlen’s operations could justify the creation of its own Logistics in this business segment. However, from a strategic point of view, Orlen simply has different priorities.

The need to scale the business

Another good reason to use 3PL services is a plan to quickly scale operations. Especially if business development is to be international.

Building a local team requires not only time and significant financial resources. It always involves knowledge of the law and culture of a given region.

It also requires completely different competencies than current warehouse or transport management. That is why companies such as Pepco work with Logistics operators.

Source: Pepco company website. Accessed November 2021.

In 2007, Pepco was still a relatively small local retail chain. Less than a hundred stores operated under the Pepco brand in Poland only.

In 2020, the Pepco Group already owned 3,000 stores in 16 European countries. More than half of them were opened after 2016.

Such a pace of business development was possible thanks to the combination of financing and cooperation with partners capable of building Logistics on a large scale. Pepco has been using DHL services for years.

Reduction of equity

Finally, cooperation with a Logistics operator or a network of operators may be the best solution if our goal is to reduce the required equity.

If an organization operates globally, there is no economic justification to own all elements of internal Supply Chain. This would simply be too expensive.

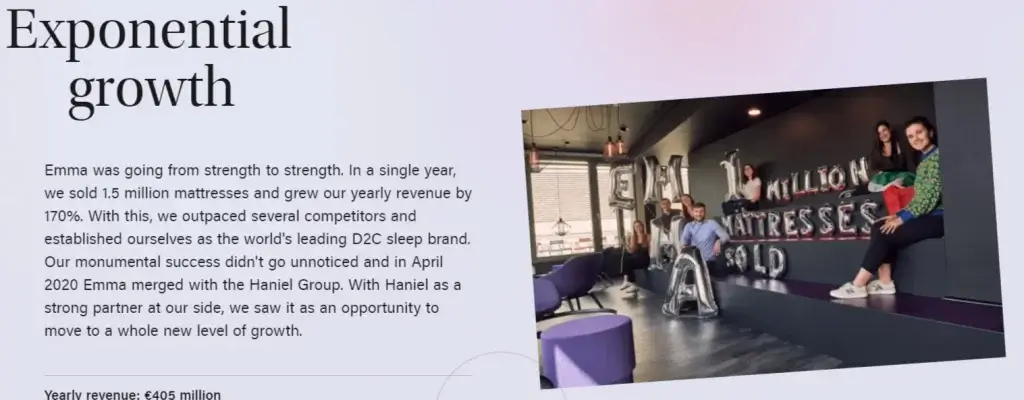

That is why many D2C ( Direct 2 Customer) companies are built in the asset-free model. Emma is one of these companies. The sleep company.

Source: Emma’s company website. Accessed November 2021.

In 2020, Emma increased its turnover from EUR 150 million to EUR 405 million. It went from Europe to 10 markets in the Asia-Pacific region. It launched deliveries to individual customers within 3 months. All without having a single warehouse of its own.

The founders of Emma came from a completely different assumption than the creators of Webvan, which is one of the biggest failures of eCommerce. Webvan was one of the first start-ups of the so-called eGrocery represented in Poland, for example, by Frisco.

The company’s investors pushed for extremely fast growth to gain a first-mover advantage. Webvan raised $1 billion in funding and allocated funds for warehouses and the purchase of a fleet of commercial vehicles. Everything before the start of sales…

Common mistakes in thinking about 3PL

Knowing in which cases cooperation with a Logistics operator is a reasonable element of the strategy, let us also pay attention to the mistakes in thinking about our relation with 3PL.

In many companies which I have been in contact with, three such errors still linger. Unfortunately, each of them individually can lead to a failure of such a relation.

It will be cheaper this way

Typically, business projects are conducted for two reasons. To ensure the development of an organization, that is to increase sales and ultimately profit. Or to ensure efficiency, that is to reduce costs.

Personally, I believe that starting cooperation with a Logistics operator solely for the second reason constitutes a risk. Of course, in some situations, the operator may be cheaper than its own Logistics.

Especially, if we consider the Supply Chain of medium and small enterprises. The operator can act as an integrator. He can get better rates for renting warehouse space, leasing equipment, and purchasing packaging materials.

As a result, he can also offer all of its customers a slightly better cost structure than any of them would be able to obtain on their own. However, if we are talking about large operations and the cost-effectiveness is not directly related to the reasons described in the section about sensible reasons for choosing 3PL, then you need to consider whether it does not achieve this through concessions in the quality of processes.

If you are particularly interested in the topic of costs, make sure to read – What should be the Logistics costs?

The operator will provide the technology

In theory, a Logistics operator should treat its Logistics not as a cost but as a way of generating revenue. Therefore, he should invest both in increasing their processing power and in modern equipment.

Unfortunately, all this is based on one more assumption – the prospect of the future of the business conducted with a client. Most Logistics contracts are currently concluded for a period of 2 to 3 years. At the same time, they save the possibility of termination with a 60 or 90-day notice.

Meanwhile, all investments that the operator can make have their payback period. Complex warehouse automation most often returns in 3 to 7 years and at the same time its implementation takes several to a dozen or so months.

That is, in total, more than the time that the operator has contractually provided. In such circumstances, the 3PL operator should not be expected to provide the customer with the latest standards and high process efficiency.

I wrote more about efficiency together with Wojtek Zaręba in the post – Efficient logistics is a strategic investment.

The operator takes the responsibility

A common mistake when thinking about working with 3PL is also the belief that outsourcing means completely handing over responsibility for the Supply Chain to the operator. You couldn’t be more wrong…

Of course, the operator assumes responsibility for the goods, for the safety of the processes carried out, for the people employed. He is also responsible for the insurance against random incidents.

However, the operator does not assume responsibility for anything that is not specified in the contract. Especially for the discrepancies between the planned and actual volumes that he has to handle.

The Logistics service contracts contain provisions on the expected level of service. All this, however, provided that the ordered receptions and releases do not deviate from the planned ones by more than a predefined percentage. Above a certain level of error, the operator simply does not guarantee anything in the world.

In other words, outsourcing physical Logistics does not exempt any organization from managing its Supply Chain. You still need to carry out the process of planning sales and operations. I also wrote about why it is worth it in the article – How to increase profits with Sales & Operations Planning?

Is outsourcing the right choice for you?

After reading this article, you should have an idea of whether Logistics outsourcing is the solution for your organization. If you come to the conclusion that it is better to stay with your own Logistics, make sure to read a series of articles on creating and optimizing Logistics:

- Warehouse project. Before you hit the first shovel.

- Warehouse equipment. Racking vertigo.

- Warehouse reorganization.

However, if you are sure that you need a Logistics operator, I encourage you to check the blog regularly. Next time I will write about how to choose the right 3PL company.

But now make sure to subscribe to the newsletter ‘Logistics Simply’. This way you will get access to the list of the 100 largest Logistics operators in Poland and a set of other materials not otherwise available.

You will also be always up to date with business and Logistics news that will allow you to create an effective Supply Chain.

The next article is coming soon.