Contrary to appearances, Logistics of an online store is not necessarily a simple task. Over the past 5 years, between 3,000 and 7,000 new online stores have been created in Poland each year. However, 60% of them did not survive the first year of operation.

On the other hand, 80% exited the market no later than before the third anniversary of the start of sales. Why, despite the increase in the eCommerce industry, entering this channel so often ends in a disaster?

Most stores close down shortly after leaving the “garage sale” stage. The previously assumed margin level turns out to be unrealistic when the daily number of orders exceeds the capacity of the owner’s family and it turns out that it is necessary to organize professional Logistics.

However, this problem is not only characteristic of new businesses. Significant retail enterprises that have been selling offline for years also find it difficult to handle the Logistics of the new sales channel. They make significant investments and face rising costs.

For example, Nike, which currently achieves ~21% of online turnover, reported a decline in operating margin from 45% to 37%. This is due to the increasing costs of Logistics connected with direct customer service.

So how to plan the Logistics of an online store to avoid the black scenario?

Logistics of an online store is not only about a package in the hands of a courier.

Observing the discussions in eCommerce groups, you can get the impression that Logistics is one of the least interesting subjects for the founders of a new enterprise. Which brings to my mind first project meetings when launching eCommerce in one of the largest retail chains in Poland.

As a Supply Chain Manager, I was invited to the discussion only after the management board decided to enter a new sales channel…

This is how it is in many companies. Selection of the stock, pricing policy, and advertising in social media are taken into consideration in the first place. And the issue of Logistics often only boils down the choice of a courier company.

However, the Logistics of an online store is not only about a package in the hands of a courier. As the organizations in which order handling has become a brake on the entire business will tell you, there are still a number of operations before and after preparing the shipment.

Receipt of goods to the warehouse, their storage, picking, sorting, bulk breaking, and packing are just a series of basic activities that are performed by warehouse employees. In addition, there are also control and administrative activities.

What is more, there are also special services if the product category or offer addressed to the customer requires it. An example may be personalizing a message to the recipient of the shipment in the case of products bought as a gift or washing and ironing of returned clothes.

Depending on the type of goods offered, the labor intensity of processes in the warehouse will be very diverse. In each case, however, handling the sales of an online store requires more work than in traditional Logistics.

What is the difference between eCommerce logistics and “traditional” retail Logistics?

Logistics supporting offline sales carries out relatively few large shipments, usually to B2B customers – own stationary stores, warehouses, or warehouses of retail chains. It operates on collective units – cartons, layers, pallets.

The Logistics of an online store most often fulfills the orders of B2C customers. These are consumers who want to receive a delivery by courier or pick it up at a selected point. It works primarily with single items, less often on cartons, and on pallets only in the case of selected categories of audio/video devices or household appliances.

The fragmented structure of shipments requires different technical equipment and imposes various functional requirements on the system on which the warehouse operates (the so-called WMS, Warehouse Management System).

I have written a bit about WMS systems some time ago with Bartłomiej Łatka in the article – Why do we need ERP, MES, WMS and the whole industry 4.0? If you have no experience with warehouse systems, make sure you read this article and then think about what and how you want to sell.

Otherwise, even the best marketing will not replace Logistics, even conducted at a decent level. As the father of advertising once said:

Great marketing will only make a bad product fail faster.

— David Ogilvy

In eCommerce, the method of preparing the package, delivery time, and the method of handling returns, or in short Logistics, is an inseparable element of the product offered to the customer.

However, a serious approach to the organization of your Logistics does not immediately mean investing in the latest technologies. Not every company should consider investing in automation, its own fleet of autonomous cars, or drones.

The choice of the model of Logistics operations and the integrated planning of operations and sales are the key issues. Decisions and processes that any determined organization is able to implement.

Your own Logistics or Logistics with an operator?

The most common models of Logistics organization used in the case of online stores are internal Logistics, cooperation with a Logistics operator, or the so-called dropshipping.

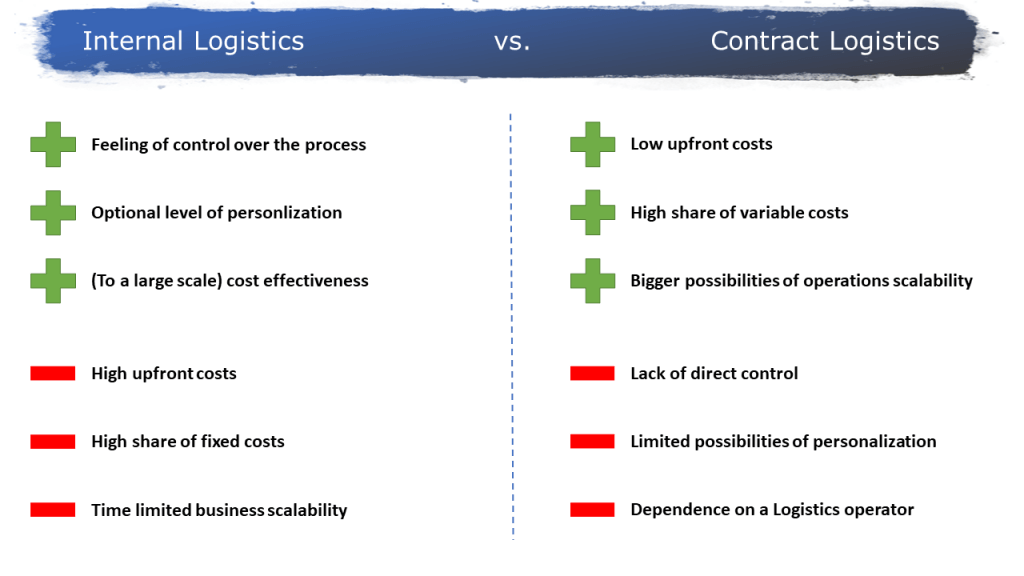

According to research by GS1 Poland, 70% of organizations selling online run their Logistics completely on their own. Most managers and business owners believe that the Logistics of an online store is not rocket science.

In addition, the feeling of maintaining control over the process and optimizing the level of costs supports this type of model. However, approaching everything on your own requires developing a number of competences and investing in your own warehouse.

Together with Andrzej Lada-Kubala, I have written about how extensive the investment process in Logistics can be. If you are considering this direction, I encourage you to read two articles first:

No way am I trying to dissuade you from investing in your own Logistics. Quite the opposite. However, it comes with high upfront costs.

In the long term, with a sufficiently large scale, it may be the most profitable model. Companies such as Zalando, MediaMarkt, Otto, Empik, and other online sales leaders are building their own distribution networks.

However, strategies should be adapted to individual situations. That is why, eventually, using the services of an operator may be a cheaper solution. Especially in the case of retail companies or production companies starting their adventure on the Internet.

Cooperation with a Logistics operator

On the one hand, a Logistics operator, thanks to the consolidation of the process of purchasing packaging and courier services, can offer lower rates to customers. Such cooperation also takes away the burden of negotiating several separate contracts.

On the other hand, operating only in the area of Logistics operations, such operator has a team remunerated at rates typical in this area.

Especially in the case of manufacturing companies, this allows you to achieve a cost advantage. In most industries, remuneration for production exceeds the rates offered to employees in Logistics.

Finally, investing in your own Logistics for eCommerce means high upfront costs. Costs related to the purchase of warehouse equipment and training of a new team.

Of course, in cooperation with an operator, these investments also have to be made. However, they are spread over time. They are covered gradually in the form of depreciation or margin, which the operator will obtain on individual operations.

In addition, entering into cooperation with a specialized Logistics organization is not only a matter of costs. The most important factor in choosing an operator is often the need to ensure the quality of processes or increase the rate of growth of operations.

Source: Own study

Cooperation with an operator is also not a solution to all the challenges posed by the Logistics of an online store. It may not be the best choice if shipments prepared for customers require a significant level of personalization. Or when the company operates on a really large scale with a stable level of turnover and does not need to scale its operations.

However, when planning to start selling online for the first time, it is worth getting to know the possibilities offered by Logistics operators. Even if the ultimate choice falls on internal Logistics, obtaining an offer from an operator will allow you to know the process that needs to be implemented. It will also help you to estimate the costs associated with running your own Logistics operations.

How about dropshipping?

Alternatively, you can still fulfill orders in the dropshipping model. This model consists in transferring the process of shipping goods to your supplier, i.e. the manufacturer or wholesaler specializing in such a process.

Dropshipping is the solution that new retail companies use most often. One of its undeniable benefits includes no need to invest in stock. The store buys the goods and commissions shipment to its customer only after receiving the payment.

This model works well for product categories with low levels of complaints and returns. Otherwise, the lack of full control over the execution of the order prolongs the process and carries the risk of losing customers’ trust.

Integrated planning of sales… and logistics

Knowing the advantages and disadvantages of possible models in Logistics, you can choose the most advantageous solution in your situation. However, this does not mean that you can consider the organization of the Supply Chain as a closed chapter of activity.

Contrary to appearances, even if we entrust the execution of orders to a Logistics operator or choose dropshipping, we still need to conduct an internal cyclical planning process for Logistics purposes.

Neither the operator nor the wholesaler will specify the required level of stock and demand for work over time for the needs of their client. Even if they make such an attempt based on historical data, they will not include promotional campaigns.

They also won’t be able to exclude all anomalies from the past. So they will create plans that will not be accurate enough to ensure the required level of order fulfillment. They may also struggle to achieve the detail level needed to optimize stock.

Demand planning on historical data only is like driving a car looking in the back mirror.

— Michael Gilliland

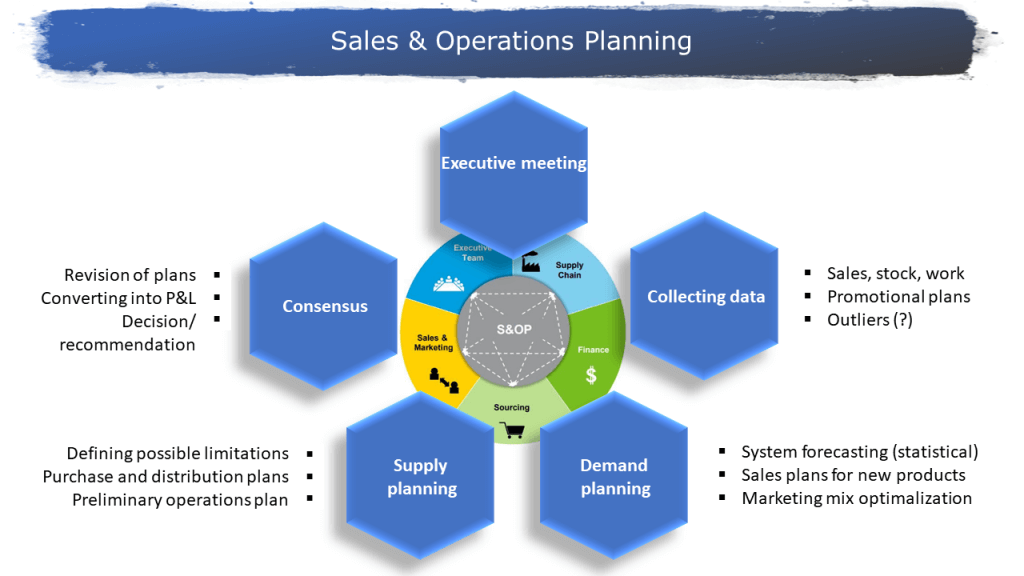

Therefore, both in the case of choosing internal Logistics and outsourcing all or selected Logistics operations, the Sales and Operations Planning process should be implemented (the so-called S&OP).

What is S&OP?

This process is the foundation of any effective Supply Chain. It integrates key functions in the organization and shows the dependencies between the actions taken. Sales and marketing begin to have a quantitative impact at the level of Logistics.

Sales & Operations Planning includes several cyclical stages:

1. Data collection: summary of sales volume and value for the last period, production level or purchase per product, and gathering information from the market;

2. Demand planning: forecasting the volume of future demand for a product, including the detection of new customer needs, as well as the possibility of shaping them;

3. Supply planning: reviewing production, purchasing, or distribution plans, and assessing possible Supply Chain constraints inside and outside the company;

4. Consensus: aligning demand plans and supply plans, ensuring that they fall within the company’s financial capabilities and goals, or identifying discrepancies;

5. Executive meeting: board review of the plan, making required decisions, and approving the final version of the operational plan for the next period.

In the case of implementing the Sales & Operations Planning process for eCommerce, a daily schedule of individual stages is usually set. So that the whole process can be carried out and repeated in a weekly planning cycle.

Source: Own study

In addition to the expected sales and the required purchase of goods, the level of customer returns is also planned, at least at the product category level.

Handling returns is always 3 – 4 times more labor intensive than operations related to sending the order to the customer. That is why taking into account returns is necessary both for the needs of internal Logistics and in cooperation with an operator.

Benefits of implementing S&OP

The S&OP process should result in the creation of one set of numbers. A plan showing the future availability of goods, possible risks on the side of sales and restocking, and goals set for the next period.

Thanks to this, the S&OP process also brings non-operational benefits. It gives a perspective on the financial side of the company’s operations. The required level of capital frozen in stock, the need for cash to finance purchases and Logistics activities, and proceeds from sales.

Therefore, the Sales & Operations Planning process is worth implementing in virtually every organization. This often requires a change in mindset and work culture throughout the company. Whereas the return on investment goes beyond Logistics alone.

I have written more about S&OP in previous blog articles:

- How to implement the S&OP process in the company? Good practices.

- Why is it so difficult to implement the S&OP process? And how to deal with it?

I can definitely recommend reading them all, even if the Logistics of the online store in your organization is not yet developed and the investment budget is not planned for this year. They rather represent a way of thinking than specific tools.

The Logistics of an online store is a never-ending story

So how to plan the Logistics of an online store? Defining the requirements in as much detail as possible, consciously choosing your operating model, and starting much earlier than the moment when the scope of Logistics responsibility is usually defined.

The most important thing is to know what and how the company intends to sell. You should calculate the costs and benefits of the possible order processing model. It is also worth considering various options to actually choose the best option.

Finally, Logistics planning is not a one-time activity. Even if we entrust the implementation of Logistics operations to external partners, we must run our own planning process. It is necessary to integrate sales and marketing activities with the expected impact on your Supply Chain.

Want to learn more about these types of topics? Make sure to sign up for the Logistics Simply newsletter. You will always be up to date with the knowledge needed to manage the Supply Chain and Logistics area. You will also receive some otherwise unavailable materials.

In the meantime, until the next post.

Note: Image used in the headline of this article courtesy of Aleksandar Littlewolf. Posted on Freepik. Thanks to the author for sharing.

1 Comment